CAM Series Product Desc ription

CAM is a new grade impact modifier for rigid PVC products, such as PVC profiles, PVC pipes, PVC panels etc. It is a copolymer which is grafted by chlorinated polyethylene and acrylic ester monomer. It offers better fusion than using chlorinated polyethylene only. It can improve the impact strength of rigid PVC under normal temperature even much lower temperature with excellent weatherable properties.

Typical Physical Properties

|

Item |

Unit |

Test Standard |

CAM750 |

CAM500 |

CAM900 |

|

Appearance |

---------- |

------------- |

White powder |

White powder |

White powder |

|

Sieve Residue(20mesh) |

% |

GB/T 2916 |

°‹2.0 |

°‹2.0 |

°‹2.0 |

|

Apparent density |

g/cm3 |

GB/T 3402-14 |

°›0.3 |

°›0.3 |

°›0.3 |

|

Volatile Content |

% |

GB/T2914-2008 |

°‹1.5 |

°‹1.5 |

°‹1.5 |

Recommend rheology , mechanical and weatherable properties testing formulation

PVC(K65) 100phr

Pb salts stabilizer 4.0phr

Calcium stearate 1.0phr

Stearate 0.2phr

PE wax(110°ś) 0.1phr

TiO2(rutile) 5.0phr

Activated light calcium carbonate 8.0phr

Processing aid 1.0phr

Impact modifier 7.0 phr

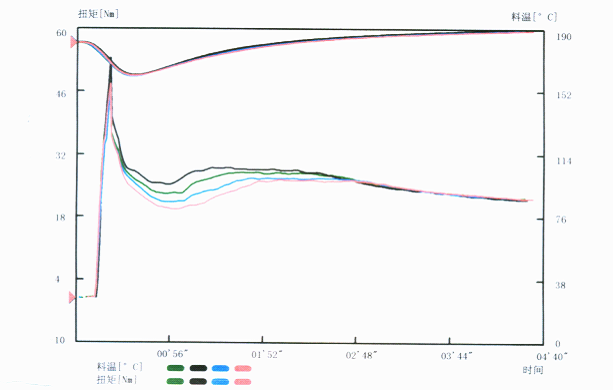

Rheology property graph

(Testing condition: 180°ś-35rpm)

|

Grade Plasticization date |

Min Torque £®Nm£© |

Max Torque £®Nm£© |

Equilibrium torque £®Nm£© |

Fusion time £®S£© |

|

°ŲCAM750

(Green line) |

23.0 |

28.3 |

22.3 |

97 |

|

°Ų CAM500

(Black line) |

25.4 |

29.6 |

22.1 |

82 |

|

°ŲCAM900

(Blue line) |

21.3 |

27.0 |

22.2 |

111 |

|

°ŲCPE3135

(Pink line) |

19.7 |

26.3 |

22.0 |

127 |

Mechanical properties comparison

|

Grade Properties |

Charpy Impact strength

(KJ/m2,) |

Hardness

(Shore A,) |

|

CAM750 |

36.6 |

82.3 |

|

CAM500 |

42.4 |

82.4 |

|

CAM900 |

32.1 |

82.1 |

|

CAM3135 |

31.5 |

82.0 |

Weatherable performance comparison of CPE,CAM in PVC products£®test standard£ļGB/T1043.1£©

Packaging PP woven bags with inner plastic bag, 25kg/bag, 500kg/bag or 550kg/bag

Safe Handling To ensure safe handling, the appropriate safety regulations should be observed. We recommend that the prospective user determine the safe handling procedures necessary for the user°Įs applications before manufacturing products. And consult the MSDS for chlorinated polyethylene before handling for additional information concerning personal protective equipment, Safety, Health and Environmental information